In modern industry and daily life, stainless steel nameplates have become an indispensable carrier of identification due to their outstanding performance and beautiful appearance. It can not only clearly convey product information, but also play roles such as decoration and anti-counterfeiting. Next, let’s take a look at the wide range of application scenarios of stainless steel nameplates and the manufacturing processes behind them.

1. Application Scenarios of Stainless Steel Nameplates

(1) Industrial equipment field

Stainless steel nameplates can be seen everywhere on all kinds of large-scale mechanical equipment and instruments. Beside the operation panel of a CNC machine tool, a stainless steel nameplate will mark important information such as the equipment model, manufacturer, technical parameters, and safety warnings, facilitating operators to quickly understand the basic situation of the equipment and ensuring its correct use and maintenance. In industries with strict environmental requirements such as chemical engineering and power, the corrosion resistance of stainless steel nameplates enables them to remain clear and legible for a long time, providing reliable information support for the safe and stable operation of equipment.

(2) Field of electronic products

The back of electronic products such as smart phones, tablet computers and laptops is often inlaid with small and exquisite stainless steel nameplates. These nameplates usually indicate the product’s model, serial number, production date, certification mark and other contents. They are not only symbols of the product’s identity, but also help shape the brand image. In addition, some high-end audio equipment and smart home products also use stainless steel nameplates to enhance the texture and grade of the products and highlight their unique quality.

(3) Transportation sector

Stainless steel nameplates are indispensable on vehicles such as cars, trains and planes. The nameplate in the engine compartment of a car records the basic information of the vehicle, such as the frame number, engine model, power, etc., and serves as an important basis for vehicle identification and after-sales maintenance. In terms of the interior and exterior of a car, stainless steel nameplates can also serve a decorative purpose, such as the brand nameplate below the car logo and the identification on the door welcome step, enhancing the overall aesthetic appeal of the vehicle. On ships and aircraft, stainless steel nameplates are also used to mark equipment information, safety instructions and other contents, adapting to the complex and changeable navigation environment.

(4) Architectural decoration field

In architectural decoration, stainless steel nameplates are often used to identify building names, floor indexes, company names, etc. Many of the corporate signboards in the lobbies of office buildings and the building direction signs in residential communities are made of stainless steel. Stainless steel nameplates can be processed through various surface treatment techniques to present multiple effects such as mirror finish, brushed finish, and sandblasting, which blend well with architectural styles and are both practical and aesthetically pleasing. In addition, some high-end hotels and clubs also use stainless steel nameplates for their house numbers and private room signs, creating an exquisite and upscale atmosphere.

(5) Daily necessities

Stainless steel nameplates are also quite common in daily necessities. On products such as thermos cups, tableware and bags, stainless steel nameplates can mark information such as brand name, material description and usage precautions. Some personalized customized gifts, such as commemorative coins, MEDALS, keychains, etc., often use stainless steel nameplates to record special commemorative meanings or engrave exclusive text and patterns on them, making them more collectible and commemorative.

2. Manufacturing Process of Stainless Steel Nameplates

(1) Stamping process

Stamping process is one of the more common methods for making stainless steel nameplates. First, a mold is made according to the design requirements. The stainless steel plate is placed in the mold, and pressure is applied through a press. Under the action of the mold, the plate undergoes plastic deformation, thereby forming the required shape and pattern. Nameplates made by stamping process feature clear lines and strong three-dimensional effect. They are suitable for manufacturing large-batch and regular-shaped nameplates, such as those in the engine compartment of automobiles.

(2) Etching process

Etching process is to form patterns and characters on the surface of stainless steel by using the principle of chemical corrosion. First, apply a layer of anti-corrosion coating on the surface of the stainless steel plate. Then, through processes such as exposure and development, transfer the designed pattern onto the anti-corrosion layer to expose the parts that need to be etched. Next, the plate is placed in the etching solution. The etching solution will corrode the exposed surface of the stainless steel, thereby forming concave patterns and characters. Etching technology can create fine and complex patterns, and is often used to make nameplates on high-end electronic products and handicrafts, which can present unique artistic effects.

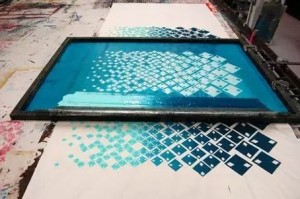

(3) Screen printing process

Screen printing is a process that uses the pressure of a squeegee to transfer ink through the holes of the screen onto the surface of stainless steel plates, forming the desired patterns and characters. Before silk-screen printing, a screen plate needs to be made first, and the designed pattern should be made into the hollowed-out parts on the screen plate. The screen printing process is relatively simple to operate and has a low cost. It is suitable for making nameplates with rich colors and diverse patterns, such as some advertising signboards and nameplates on daily necessities.

(4) Laser engraving process

Laser engraving technology utilizes a laser beam with high energy density to instantly melt or vaporize the material on the surface of stainless steel, thereby forming precise patterns and characters. Laser engraving has the advantages of high precision, fast speed and no need for molds. It can produce very fine lines and complex patterns, and the engraving effect is permanent and not easy to wear or fade. Laser engraving technology is often used to make nameplates for high-end products, such as luxury goods and precision instruments, which can reflect the high quality and uniqueness of the products.

(5) Surface treatment process

In order to enhance the aesthetic appeal and performance of stainless steel nameplates, various surface treatments are also required. Common surface treatment processes include mirror finishing. Through polishing and other methods, the surface of stainless steel can achieve a mirror-like luster effect, making it look high-end and elegant. Brushing treatment is to form a uniform filamentous texture on the surface of stainless steel through mechanical friction, enhancing the texture and anti-slip performance. Sandblasting treatment involves using high-pressure air flow to spray sand particles onto the surface of stainless steel, creating a rough frosted effect that offers a unique visual and tactile experience. In addition, stainless steel nameplates can be endowed with different colors and surface textures through processes such as electroplating and baking varnish, meeting diverse design requirements.

Stainless steel nameplates play a significant role in various fields with their wide range of application scenarios and rich and diverse manufacturing processes. With the continuous progress and innovation of technology, the performance and aesthetic appeal of stainless steel nameplates will be further enhanced, bringing more convenience and surprises to our lives and production.

Post time: Jun-27-2025